Industrial Pump Selection: Centrifugal Pumps vs. Positive Displacement Pumps, the Truth About Pump Efficiency, Pump Maintenance Costs, and Why Engineers Trust Grundfos Pumps

That new pump humming away in your facility might be a six-figure mistake waiting to happen. Making the wrong industrial pump selection is one of the costliest, and most common, errors in plant operations.

You see it in the climbing energy bills and the frustratingly high pump maintenance costs. You chose a pump to move fluid, but instead, it’s causing cavitation, fighting against viscosity, and slowly destroying itself, taking your production schedule down with it. The problem often starts by treating all pumps as equal.

This guide is your blueprint for getting it right every single time. We are demystifying the critical choice between the two workhorses of the industry so you can protect your budget and boost your uptime.

We’ll break down exactly when to use centrifugal pumps versus positive displacement pumps, and why focusing only on initial pump efficiency is a trap. You will also see how premium models, like Grundfos pumps, are engineered to prevent these exact failures, saving you a fortune over the life of the equipment.

Choosing the wrong pump for the job is one of the fastest ways to drain a plant’s budget. The right industrial pump selection is not just about moving fluid; it’s about protecting your bottom line from high energy bills and unexpected downtime [1][2][5].

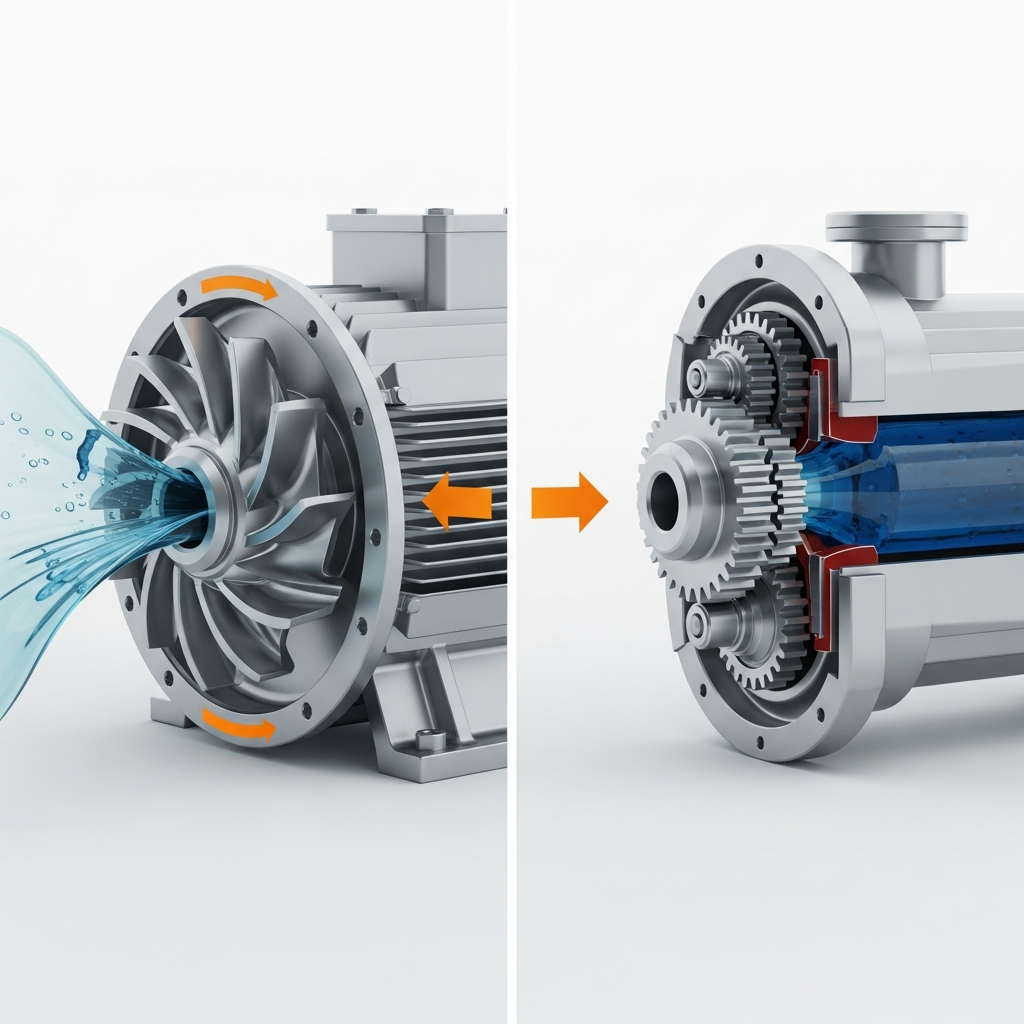

It all comes down to two main types of pumps: centrifugal pumps and positive displacement pumps. Think of centrifugal pumps as fans for liquid. They use a spinning impeller to create flow, which is great for moving water-like fluids quickly. However, their pump efficiency drops fast when the liquid gets thicker or pressure changes, leading to damage and higher energy use [1][2][3][7].

On the other hand, positive displacement pumps work like a syringe, moving a fixed amount of fluid with each cycle. This gives them steady performance no matter the pressure, making them perfect for thick or sensitive liquids [1][4][5].

Getting this choice wrong leads to soaring pump maintenance costs and wasted energy. That’s why many engineers look to Grundfos pumps as a benchmark. By choosing a high-efficiency model designed for a specific job, they ensure reliable operations and avoid costly mistakes from the start [1][2][7].

Pump Efficiency Explained: Centrifugal vs. Positive Displacement

Pump efficiency is a measure of how well a pump turns energy into fluid movement [8][9][12]. Think of it like gas mileage for your car. A pump running at its best uses the least amount of energy to do its job, which is critical for any industrial pump selection because it directly impacts your energy bills and long-term pump maintenance costs.

Here’s how the two main types stack up:

- Centrifugal Pumps: These pumps use a spinning impeller to create flow, making them great for moving large volumes of thin fluids like water at high speeds [8][9][12]. However, their efficiency is tied to a specific "sweet spot." If pressure in the system changes, the flow rate changes, and pump efficiency can drop sharply. Running them too far off their ideal curve can lead to damage and higher energy use [8][12].

- Positive Displacement Pumps: Instead of spinning fluid, positive displacement pumps trap a fixed amount of liquid and force it out, providing a constant, steady flow no matter the pressure [8][10][11]. This makes them perfect for thick, sticky, or shear-sensitive fluids. In fact, their efficiency often improves as the fluid gets thicker [8][9][11]. The one major rule is that they must never be run against a closed valve, as the pressure will build until something breaks [10][12].

When it comes to setting the standard for optimized energy use, Grundfos pumps are often the benchmark. The company engineers both centrifugal pumps and positive displacement models with advanced designs that balance performance, energy consumption, and reliability to lower the total cost of ownership [14].

Where It Breaks: Common Failures in Real-World Installations

The wrong industrial pump selection is a ticking time bomb. It doesn't just lower pump efficiency; it causes expensive, real-world failures that can shut down an entire operation.

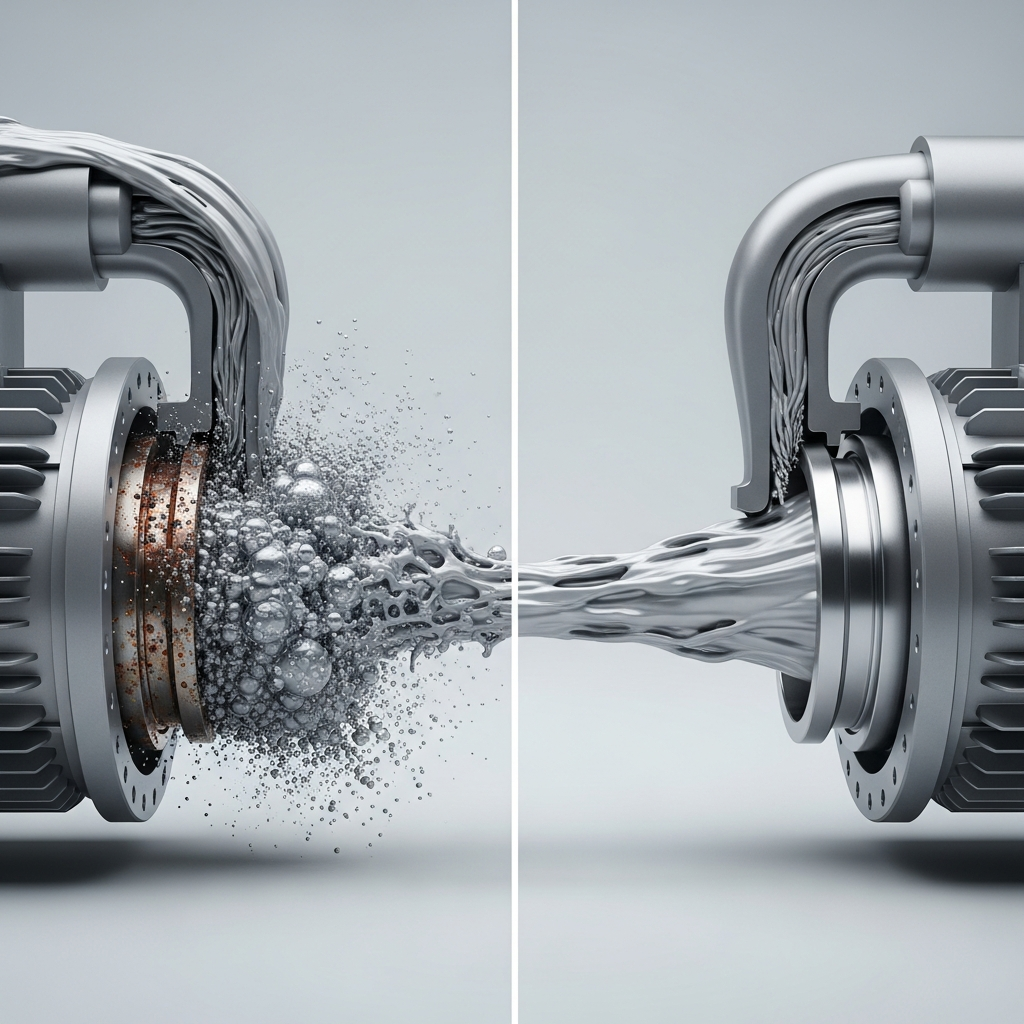

One of the most common mistakes happens in chemical processing. If you use centrifugal pumps to move thick, high-viscosity fluids (over 850 cSt), their performance plummets. Frictional losses cause them to overheat and reduce flow, leading to process downtime [15][16][19]. This is where positive displacement pumps shine, as they deliver a steady flow no matter how thick the liquid gets, preventing production halts that cost thousands [16][17].

Another major issue is flow rate instability. Centrifugal pumps are designed to work best at a specific point on their efficiency curve. If system pressure changes, their flow rate can drop dramatically [15][16][21]. This creates system imbalances, especially in applications like water transfer. In contrast, positive displacement pumps provide a consistent flow regardless of pressure changes, avoiding constant adjustments [15][19].

These issues directly lead to soaring pump maintenance costs. When a centrifugal pump operates outside its sweet spot, it can cause cavitation. This is when tiny vapor bubbles form and collapse with incredible force, eroding the pump's internal parts like the impeller [15][19]. This wear and tear means more downtime and frequent, costly part replacements.

This is where smart design makes a difference. Grundfos pumps, for example, are built to mitigate these risks. Their centrifugal models feature robust, high-speed impellers and optimized efficiency curves that tolerate pressure changes better, reducing the chance of cavitation [20]. By designing for a wider range of applications, they help engineers avoid the mismatches that lead to failures and high costs in the first place [20].

The 10-Year Cost View: Total Cost of Ownership Comparison

When it comes to industrial pump selection, the initial price tag is just the tip of the iceberg. The total cost of ownership over a decade reveals the real winner. For applications with thick fluids or changing pressure, centrifugal pumps often end up costing more than positive displacement pumps because of lower pump efficiency and higher wear and tear [22][23][24].

Let's break down the hidden expenses that add up over 10 years:

- Pump Maintenance Costs: While centrifugal pumps have a simpler design, they wear out faster when handling viscous fluids (over 850 cSt) or operating off their peak performance curve. This leads to more frequent part replacements and higher long-term pump maintenance costs [22][23]. Positive displacement pumps, though more complex initially, maintain steady performance and require less servicing in these demanding roles [22][23].

- Energy Consumption: The pump efficiency of centrifugal pumps plummets when fluid viscosity or pressure changes, causing them to burn through energy [22][23][24]. In contrast, positive displacement pumps deliver consistent flow and efficiency, which significantly lowers energy bills over a decade in tough industrial settings [22][23].

- Downtime & Replacements: Centrifugal pumps are sensitive. They are prone to damage from cavitation (air bubbles) and cannot self-prime, leading to downtime and extra costs for replacing impellers and seals [22]. A mismatched pump is a recipe for premature failure and a blown budget [22][26].

This is where smart engineering makes a difference. Grundfos pumps are designed to deliver a lower total cost of ownership. Their robust centrifugal models are highly efficient for low-viscosity systems, minimizing energy use and downtime [28]. For more demanding jobs, Grundfos's expert selection ensures the pump operates at its peak efficiency, cutting energy waste and preventing the costly outages common with generic pumps [22][23][28].

Choosing the Right Pump: A Strategic Framework for Engineers

Making the right industrial pump selection comes down to three main things: the type of fluid you're moving, the pressure you need, and your target flow rate [29][30][31]. Getting this wrong can lead to huge energy bills and constant headaches.

Centrifugal pumps are your go-to for moving thin liquids like water or chemicals at high flow rates [29][30][33]. They are simple, have fewer moving parts, and usually cost less upfront [31][33]. However, their pump efficiency drops fast when dealing with thick fluids (high viscosity) or if the pressure changes too much [29][30].

On the other hand, positive displacement pumps are perfect for thick, heavy fluids and situations where you need a steady, consistent flow no matter what the pressure is doing [29][30][35]. They can even handle liquids with gases or solids in them [29]. While they can be more complex, their ability to handle tough jobs makes them incredibly reliable [31][33].

Thinking beyond the sticker price is key. True pump efficiency is about matching the pump to the job to save energy over its lifetime [30][31]. You also have to consider long-term pump maintenance costs. A cheaper pump that fails often will cost you far more in downtime and repairs than a reliable one [29][31][33].

This is why partnering with a brand focused on total performance matters. Experts often look to Grundfos pumps because they are built for reliability and long-term value. Their robust centrifugal designs and engineering support help you focus on lifecycle performance, ensuring you get the best return on your investment for years to come [34].

Citations:

[1]: https://cbeuptime.com/centrifugal-vs-positive-displacement-pumps/

[2]: https://www.anchorpumps.com/blog/positive-displacement-pumps-vs-centrifugal-pumps-complete-guide/

[3]: https://hmft.com/blogs/news/comparing-hot-oil-pumps-centrifugal-vs-positive-displacement

[5]: https://www.gainesvilleindustrial.com/blog/centrifugal-vs-positive-displacement-pumps/

[6]: https://www.youtube.com/watch?v=o0Bh7Xwwa9M

[7]: https://api.grundfos.com/literature/Grundfosliterature-5448843.pdf

[8]: https://cbeuptime.com/centrifugal-vs-positive-displacement-pumps/

[9]: https://hmft.com/blogs/news/comparing-hot-oil-pumps-centrifugal-vs-positive-displacement

[11]: https://www.gainesvilleindustrial.com/blog/centrifugal-vs-positive-displacement-pumps/

[12]: https://www.daepumps.com/resources/positive-displacement-pump-vs-centrifugal-pump/

[13]: https://www.youtube.com/watch?v=o0Bh7Xwwa9M

[14]: https://api.grundfos.com/literature/Grundfosliterature-5448843.pdf

[15]: https://cbeuptime.com/centrifugal-vs-positive-displacement-pumps/

[16]: https://www.anchorpumps.com/blog/positive-displacement-pumps-vs-centrifugal-pumps-complete-guide/

[17]: https://hmft.com/blogs/news/comparing-hot-oil-pumps-centrifugal-vs-positive-displacement

[18]: https://www.youtube.com/watch?v=o0Bh7Xwwa9M

[19]: https://www.pumpsalesdirect.co.uk/blog/positive-displacement-pumps-vs-centrifugal-pumps/

[20]: https://api.grundfos.com/literature/Grundfosliterature-5448843.pdf

[21]: https://blog.hayespump.com/blog/positive-displacement-pump

[22]: https://cbeuptime.com/centrifugal-vs-positive-displacement-pumps/

[23]: https://www.anchorpumps.com/blog/positive-displacement-pumps-vs-centrifugal-pumps-complete-guide/

[24]: https://hmft.com/blogs/news/comparing-hot-oil-pumps-centrifugal-vs-positive-displacement

[26]: https://www.gainesvilleindustrial.com/blog/centrifugal-vs-positive-displacement-pumps/

[27]: https://www.youtube.com/watch?v=o0Bh7Xwwa9M

[28]: https://api.grundfos.com/literature/Grundfosliterature-5448843.pdf

[29]: https://cbeuptime.com/centrifugal-vs-positive-displacement-pumps/

[30]: https://www.anchorpumps.com/blog/positive-displacement-pumps-vs-centrifugal-pumps-complete-guide/

[31]: https://hmft.com/blogs/news/comparing-hot-oil-pumps-centrifugal-vs-positive-displacement

[32]: https://www.youtube.com/watch?v=o0Bh7Xwwa9M

[33]: https://www.pumpsalesdirect.co.uk/blog/positive-displacement-pumps-vs-centrifugal-pumps/

[34]: https://api.grundfos.com/literature/Grundfosliterature-5448843.pdf

[35]: https://blog.hayespump.com/blog/positive-displacement-pump

[36]: https://cbeuptime.com/centrifugal-vs-positive-displacement-pumps/

[37]: https://www.anchorpumps.com/blog/positive-displacement-pumps-vs-centrifugal-pumps-complete-guide/

[38]: https://hmft.com/blogs/news/comparing-hot-oil-pumps-centrifugal-vs-positive-displacement

[40]: https://www.gainesvilleindustrial.com/blog/centrifugal-vs-positive-displacement-pumps/

[41]: https://www.youtube.com/watch?v=o0Bh7Xwwa9M

[42]: https://www.castlepumps.com/info-hub/positive-displacement-vs-centrifugal-pumps

[43]: https://cbeuptime.com/centrifugal-vs-positive-displacement-pumps/

[44]: https://hmft.com/blogs/news/comparing-hot-oil-pumps-centrifugal-vs-positive-displacement

[46]: https://www.gainesvilleindustrial.com/blog/centrifugal-vs-positive-displacement-pumps/

[47]: https://www.daepumps.com/resources/positive-displacement-pump-vs-centrifugal-pump/

[48]: https://www.youtube.com/watch?v=o0Bh7Xwwa9M

[49]: https://api.grundfos.com/literature/Grundfosliterature-5448843.pdf